Release time:2023-12-21 12:32:55 Hits: Current position: Home > News

This article mainly introduces:

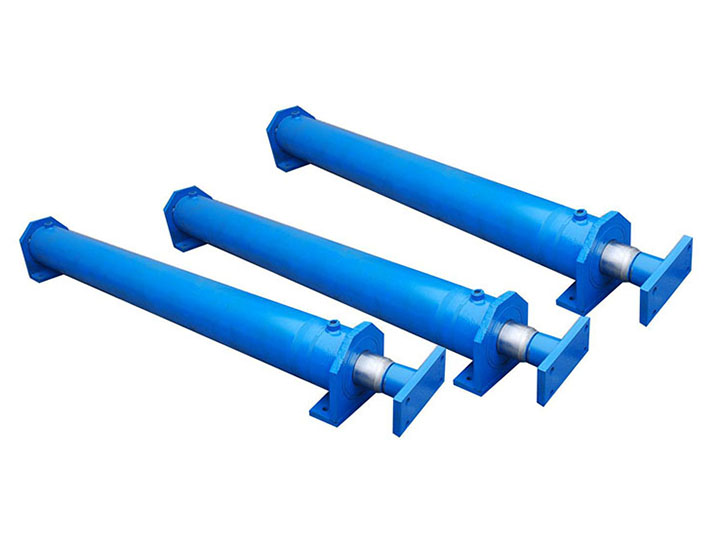

Romania hydraulic cylinder,push and pull the cylinder manufacturer,push and pull the cylinder

(Romania push and pull the cylinder,produced by Hengyu Hydraulic Cylinder Factory)

push and pull the cylinder are widely used in Romania,because of no need for deceleration device,long service life,smooth movement.So our company has designed push and pull the cylinder for customers from Romania.

Causes and countermeasures of oil push and pull the cylinder leakage: Cast iron ring seal allows a certain degree of internal leakage. The impurities in the push and pull the cylinder will lead to premature wear of the piston seal, replace the piston seal; If the push and pull the cylinder is visibly scarred, the push and pull the cylinder must be replaced. It can be pressurized at one end of the push and pull the cylinder and opened at the other end of the oil port to observe whether there is obvious internal leakage at the end of the oil port. Most push and pull the cylinder piston drift may not come from the push and pull the cylinder, the above method to determine the push and pull the cylinder without internal leakage is helpful to determine the problem of the hydraulic system related components.

push and pull the cylinder spool stuck or valve hole blocked How to solve: When the flow valve or direction valve spool stuck or valve hole blocked, the push and pull the cylinder prone to misoperation or action failure. At this time, the contamination of the oil should be checked; Check whether dirt or colloidal deposits are stuck in the spool or blocking the valve hole; Check the wear of the valve body, clean and replace the system filter, clean the fuel tank, and replace the hydraulic medium.

When installing the push and pull the cylinder pipe, the pipe should be cleaned after installation, and should not pass through the push and pull the cylinder block, and the by-pass pipe must be installed in front of the oil port of the push and pull the cylinder block. This is important. Otherwise, the foreign body in the pipeline will enter the push and pull the cylinder, and once it enters, it is difficult to exclude it, but it becomes a foreign body transported to the push and pull the cylinder. Moreover, when cleaning, the removal method of foreign bodies entered in the installation pipeline operation should be considered. In addition, the corrosion in the pipe should be pickling and other procedures before the pipe installation, and the rust must be completely removed.

The meaning of the push and pull the cylinder model marked by the push and pull the cylinder manufacturer: for example, 160/100-1150, its meaning: from a professional point of view, 160 refers to the push and pull the cylinder diameter, which is 160mm, and the 100 behind refers to the rod diameter, which is 100mm. The 1150 refers to the push and pull the cylinder stroke, which is 1150mm. Therefore, on this point, we should have a correct understanding and can not make mistakes.

What causes hydraulic cylinder oil leakage?

1. Internal leakage (1) The wear ring on the piston is seriously worn, leading to friction between the piston and the cylinder liner, and finally strain the cylinder liner, piston and seal; 2) Seal long-term use failure, piston seal (mostly U, V, Y ring, etc.) aging; 3) The hydraulic oil is dirty, and a large number of impurities enter the cylinder and wear the piston seal to bad; 2. External leakage 1) cylinder inlet and outlet tubing joint cracking; (This I see in the actual work is still more) 2) The piston rod extension end with the piston rod seal damage, mostly due to the piston cylinder is caused by hair, but also caused by aging; 3) The seal between the extended end of the piston rod and the liner is damaged.

PLC+ inverter + motor + pump + solenoid valve + cylinder combination, can control the accuracy of cylinder position?

In the case of extremely high accuracy requirements, you can not, please consider a few problems: 1, hydraulic oil can be compressed, it is elastic like a spring. Therefore, in the general hydraulic servo system, the valve control is far more accurate than the pump control. Because the valve can be installed very close to the hydraulic cylinder, or even installed on the hydraulic cylinder, but the pump must go through the tubing and then into the hydraulic cylinder, there is a long distance, which greatly reduces the rigidity of the system and increases the difficulty of control. 2, the quantitative pump is first of all leaking, and there is 10%-20% flow pulsation. Secondly, and more unfortunately, the leakage of the pump is related to the pressure and is non-linear.