Release time:2023-11-12 14:24:06 Hits: Current position: Home > News

This article mainly introduces:

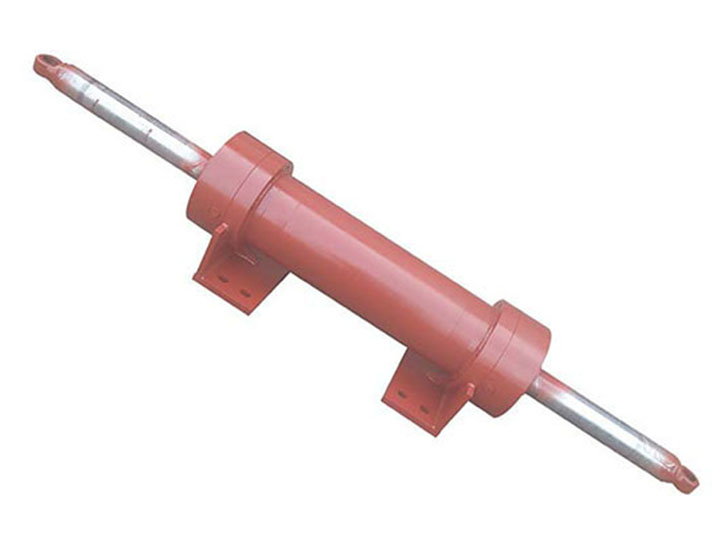

Guatemala hydraulic cylinder,track steering cylinder manufacturer,track steering cylinder

(Guatemala track steering cylinder,produced by Hengyu Hydraulic Cylinder Factory)

track steering cylinder are widely used in Guatemala,because of high work efficiency,excellent fatigue and impact resistance,no need for deceleration device.So our company has designed track steering cylinder for customers from Guatemala.

If air enters the hydraulic system, the track steering cylinder will not operate normally, mainly because there is a leak in the system. At this time, check the liquid level of the hydraulic tank, the seals and fittings on the oil suction side of the hydraulic pump, and whether the oil suction filter is too dirty. If so, the hydraulic oil should be replenished, seals and fittings should be treated, and the coarse filter element should be cleaned or replaced.

track steering cylinder body inspection: The inner surface of the track steering cylinder and the piston seal are the main factors causing the leakage in the track steering cylinder, if the track steering cylinder has a longitudinal tensile mark, even if the new piston seal is replaced, it can not effectively eliminate the fault, the inner surface of the track steering cylinder mainly checks whether the dimensional tolerance and shape and position tolerance meet the technical requirements, there is no longitudinal tensile mark, and measures the depth of the longitudinal tensile mark, in order to take the corresponding solution.

Classification of track steering cylinder: according to the mode of movement it can be divided into linear reciprocating movement type and rotary swing type; According to the effect of liquid pressure, it can be divided into single acting type and double acting type. According to the structure, it can be divided into piston type, plunger type, multistage telescopic sleeve type, pinion and rack type, etc. According to the installation form can be divided into rod, earring, foot, hinge shaft and so on; According to the pressure grade can be divided into 16Mpa, 25Mpa, 31.5Mpa and so on.

What kind of process is used in the track steering cylinder to make high-quality track steering cylinder products: the body is the main component of the track steering cylinder, mining single pillar, hydraulic support, gun tube and other products, and its processing quality directly affects the life and reliability of the entire product. Body processing requirements are high, the internal surface roughness requirements are Ra0.4 ~ 0.8&um, the coaxiality, wear resistance requirements are strict. The basic feature of body is deep hole processing, which has always troubled the processing personnel. The track steering cylinder products of our company mainly use rolling processing, because the surface layer has surface residual compressive stress, which helps to close the surface micro-cracks and hinder the expansion of erosion. Thus, the corrosion resistance of the surface can be improved, and the fatigue crack can be delayed or expanded, and the fatigue strength of the body can be improved. The correct rolling process of the track steering cylinder block: broaching block - fine boring block - grinding block. The rolling method is: broaching block - fine boring block - rolling block, the process is 3 parts, but the time is compared: grinding 1 meter of the block is about 1-2 days, rolling 1 meter of the block is about 10-30 minutes. Input comparison: grinding machine or quilting machine (tens of thousands - millions), rolling knife (ten thousand - tens of thousands). After rolling, the surface roughness of the hole decreases from RA3.2-6.3um before rolling to RA0.4-0.8&um, the surface hardness of the hole increases by about 30%, and the fatigue strength of the inner surface of the track steering cylinder increases by 25%. If the service life of the track steering cylinder is only considered, it is increased by 2 to 3 times, and the efficiency of the boring and rolling process is about 3 times higher than that of the grinding process. track steering cylinder misoperation or operation failure may be caused by the following reasons, you can start from these aspects of the investigation: (1) spool stuck or valve hole blocked. When the spool of the flow valve or direction valve is stuck or the valve hole is blocked, the track steering cylinder is prone to misoperation or operation failure. At this time, the contamination of the oil should be checked; Check whether dirt or colloidal deposits are stuck in the spool or blocking the valve hole; Check the wear of the valve body, clean and replace the system filter, clean the fuel tank, and replace the hydraulic medium. (2) The piston rod and track steering cylinder are stuck or the track steering cylinder is blocked. At this time, no matter how to manipulate, the track steering cylinder does not move or moves very little. At this time, check whether the piston and piston rod seal is too tight, whether it enters the dirt and gum deposits: whether the shaft line of the piston rod and the track steering cylinder is in the center, whether the wearing parts and seals are invalid, and whether the load is too large.

Why is the hydraulic cylinder of the larger excavator arm upside down?

The weight of the excavating arm of a large excavator will be very heavy, and an oil cylinder has two cavities, one is a rod cavity, and the other is a rodless cavity. The lifting force of the excavator is the product of the ortho-projection area of the piston rod cavity by the oil pressure, so the strength of the rodless cavity is much greater than that of the rod cavity. And the parallel bars with the piston rod facing down are also conducive to assembly and future maintenance. So a large excavator has to keep the cylinder facing down.

How to limit cylinder push rod rotation?

In general, the push-rod rotation can be limited after the push-rod is connected to the pushed mechanism. For example, the push rod is hinged with the push mechanism, or the push mechanism itself is guided, which can limit the rotation of the push rod.