Release time:2023-11-12 11:05:53 Hits: Current position: Home > News

This article mainly introduces:

Ethiopia hydraulic cylinder,vehicle hydraulic cylinder manufacturer,vehicle hydraulic cylinder

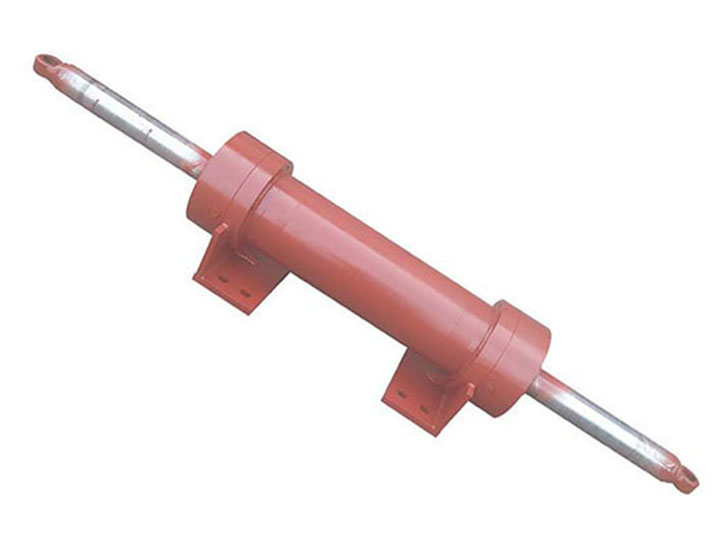

(Ethiopia vehicle hydraulic cylinder,produced by Hengyu Hydraulic Cylinder Factory)

vehicle hydraulic cylinder are widely used in Ethiopia,because of long service life,smooth movement,high work efficiency.So our company has designed vehicle hydraulic cylinder for customers from Ethiopia.

The wear of the hard chromium plating layer of the vehicle hydraulic cylinder is mostly caused by the grinding of the friction iron powder of the piston, and the wear is faster when there is water in the middle. Corrosion caused by the contact potential difference of the metal only occurs in the part of the piston contact, and the corrosion occurs in a point pattern. As mentioned above, when there is moisture in the middle, it will promote the development of corrosion. Compared with castings, the contact potential difference of copper alloy is higher, so the corrosion degree of copper alloy is more serious.

If the vehicle hydraulic cylinder operation failure, you can start from these aspects to troubleshoot: (1) the hydraulic system control pressure is too low. The throttling resistance in the control line may be too large, the flow valve is improperly adjusted, the control pressure is inappropriate, and the pressure source is disturbed. At this time, the control pressure source should be checked to ensure that the pressure is adjusted to the specified value of the system; (2) Air enters the hydraulic system. Mainly because there is a leak in the system. At this time, check the liquid level of the hydraulic tank, the seals and fittings on the oil suction side of the hydraulic pump, and whether the oil suction filter is too dirty. If so, the hydraulic oil should be replenished, seals and fittings should be treated, and the coarse filter element should be cleaned or replaced. (3) The initial action of the vehicle hydraulic cylinder is slow. In the case of low temperature, the hydraulic oil viscosity is large, poor flow, resulting in slow vehicle hydraulic cylinder action. The improvement method is to replace the hydraulic oil with better viscosity and temperature performance If the vehicle hydraulic cylinder is weak and cannot push the load, please check the internal leakage problem. The internal leakage of the vehicle hydraulic cylinder includes the leakage caused by excessive wear of the vehicle hydraulic cylinder block seal, the piston rod and the seal cover seal and the piston seal. The cause of sealing leakage between the piston rod and the seal cover is that the seal is wrinkled, squeezed, torn, worn, aging, deterioration, deformation, etc., and a new seal should be replaced at this time. The main cause of excessive piston seal wear is improper adjustment of the speed control valve, resulting in excessive back pressure and improper seal installation or hydraulic oil contamination. The second is that foreign bodies enter the assembly and the quality of sealing materials is not good. The result is that the action is slow and weak, and in serious cases, it will cause damage to the piston and vehicle hydraulic cylinder, and the phenomenon of "pulling the vehicle hydraulic cylinder" appears. The treatment method is to adjust the speed control valve, and the necessary operations should be done according to the installation instructions.

vehicle hydraulic cylinder installation precautions: Before installing the vehicle hydraulic cylinder into the system, the parameters on the vehicle hydraulic cylinder label should be compared with the parameters when ordering. The base of the vehicle hydraulic cylinder must have sufficient stiffness, otherwise the vehicle hydraulic cylinder will bend upward into a bow when pressurized, so that the piston rod will bend.

When the vehicle hydraulic cylinder is customized, if there are high requirements for the quality of the vehicle hydraulic cylinder, it is best to use rolling processing, because the surface layer has surface residual compressive stress, which helps to close the surface of the small crack, preventing the expansion of erosion. Thus, the corrosion resistance of the surface can be improved, and the fatigue crack can be delayed or expanded, and the fatigue strength of the vehicle hydraulic cylinder can be improved. By rolling forming, a cold working hardening layer is formed on the rolling surface, which reduces the elastic and plastic deformation of the contact surface of the grinding pair, thereby improving the wear resistance of the inner wall of the vehicle hydraulic cylinder and avoiding the burn caused by grinding. After rolling, the reduction of surface roughness value can improve the matching property.

How to produce good quality hydraulic cylinder?

According to the principle of quality control, it is considered from five aspects: people, machine, material, method and environment. 1, People, refers to the processing and assembly operators. Their skills, professional qualifications, literacy should meet the requirements of production. For example, do your machining workers have the required grade certificate? Do your welders have welding certificate? 2, Machine, refers to your production equipment. Production cylinders have requirements for processing equipment. For example, the piston rod requires chrome grinding. Can your equipment meet the need? 3, Material. The material you use should meet the quality requirements. For example, the sealing ring of PARK and domestic goods is different. Material is also very important. 4. Method refers to the process method. Do your processing and assembly processes meet the requirements? 5, Environment. The environment shall be neat and orderly, clean and hygienic. It is especially important for the hydraulic cylinder production enterprise environment. Can your assembly shop site be clean and dust-free? Quality inspection is also a focus of control. Products should do pressure test, leakage test. The test pressure should reach 1.25 times the design pressure. If you can't maintain pressure, what about quality? You may not be able to do the whole process of cylinder production, you can take the method of OEM. Taking advantage of the strengths of specialized manufacturers, you contract out what you need and then assemble it yourself. But the principle of quality control is the same.

What are the four cylinders of the truck crane?

The four cylinders of the truck crane generally refer to the telescopic cylinder of the boom (to adjust the length of the boom), the variable amplitude cylinder of the boom (to adjust the elevation Angle of the boom), the horizontal telescopic cylinder of the support leg and the vertical cylinder of the support leg.