Release time:2023-11-08 15:23:43 Hits: Current position: Home > News

This article mainly introduces:

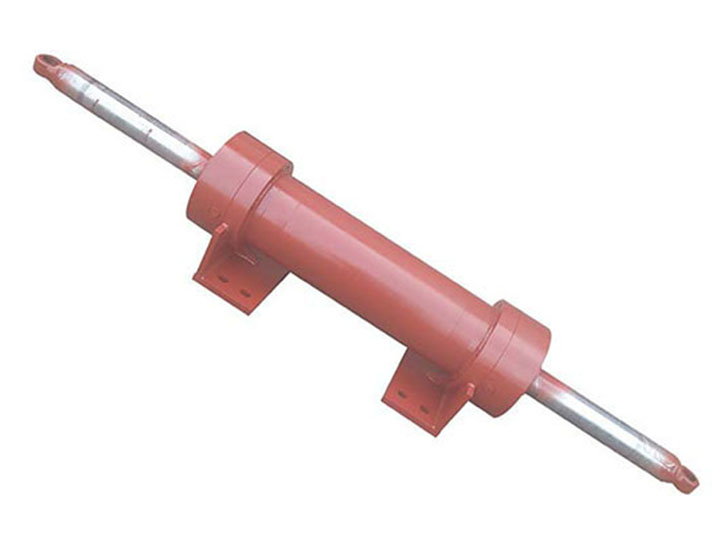

Ethiopia hydraulic cylinder,track steering cylinder manufacturer,track steering cylinder

(Ethiopia track steering cylinder,produced by Hebei Hengyu company)

track steering cylinder are widely used in Ethiopia,because of no need for deceleration device,long service life,smooth movement.So our company has designed track steering cylinder for customers from Ethiopia.

The role of the track steering cylinder in the mold industry: the track steering cylinder has a variety of uses in the mold, one is that the core distance is very large, or because of the mechanism of the product, only the track steering cylinder is reasonable or more cost saving. Let the side core be extracted before opening the mold. Hot runner is mainly based on the product to decide, sometimes customers require the use of hot runner, the price is more expensive, but there are many benefits, you can save raw materials, shorten the molding cycle The track steering cylinder has an irreplaceable role in the heavy industry production process: it is mainly used in places that need to support heavy objects for a long time, and it can still support heavy objects when the oil pressure is removed, and it is safe and reliable. Can be used underwater, single action, load reversion, nut self-locking to make the load safer, especially in large projects, is easy to operate control and self-locking jack, designed with a safety pressure retaining device, built-in pressure relief valve to prevent overload, to protect the self-locking jack to facilitate safe operation. The connection of the device is connected by high pressure hose and threaded joint, which has the advantages of fast use and overcoming the shortcomings of fast traditional joint oil leakage. It is mainly used for equipment installation and toppling operation in various industries such as electric power, construction, machinery manufacturing, mining, railway bridge, shipbuilding and so on.

When the track steering cylinder is repaired, its inner and outer diameter and roundness should be accurately measured. If the inner hole of the track steering cylinder is badly worn, it can be repaired by grinding the mandrel or honing on the boring machine. If the piston is worn, it can be repaired by electroplating, and serious wear should be replaced.

If the track steering cylinder slips or crawls, please check whether there is astringency inside the track steering cylinder, because the internal parts of the track steering cylinder are improperly assembled, the parts are deformed, worn or the shape and position tolerance is excessive, the action resistance is too large, so that the piston speed of the track steering cylinder changes with the different stroke position, and the slip or crawl occurs. Most of the reasons are due to poor assembly quality of parts, surface scars or sintered iron filings, so that the resistance increases, the speed decreases. For example, the piston is different from the piston rod or the piston rod is bent, the track steering cylinder or the piston rod is offset from the mounting position of the guide rail, and the sealing ring is too tight or too loose. The solution is to repair or adjust, replace damaged parts and remove iron filings.

When the track steering cylinder is installed, it is necessary to ensure that the direction of the connecting head at the top of the piston rod should be consistent with the direction of the track steering cylinder head, earring (or middle hinge shaft), and ensure the straightness of the whole piston rod during the advance and return process to prevent rigid interference and cause unnecessary damage.

CNC lathe rotary cylinder oil leakage and treatment methods

Oil leakage often occurs when the cylinder (especially the hollow cylinder) of the CNC lathe is installed. First check the cylinder yaw, be sure to reach or close to the required value, generally the cylinder requires the outer beat within 1 wire. Otherwise, too much beating is sure to leak oil. Then check whether the tubing is smoothly downward at a certain Angle, and can not bend. Look at the pipe outlet can not go into the oil level, to a little higher. Otherwise, there's back pressure and it's gonna leak.

The difference between the overall cylinder and the separate cylinder of the truck?

The whole cylinder is cast in one piece, and such a cylinder generally does not leak oil. Split cylinder refers to two welded, easy to leak oil in the welding place, resulting in damage to the cylinder, or its body can not get up, many people do not use this kind of cylinder now.