Release time:2023-12-11 09:05:26 Hits: Current position: Home > News

This article mainly introduces:

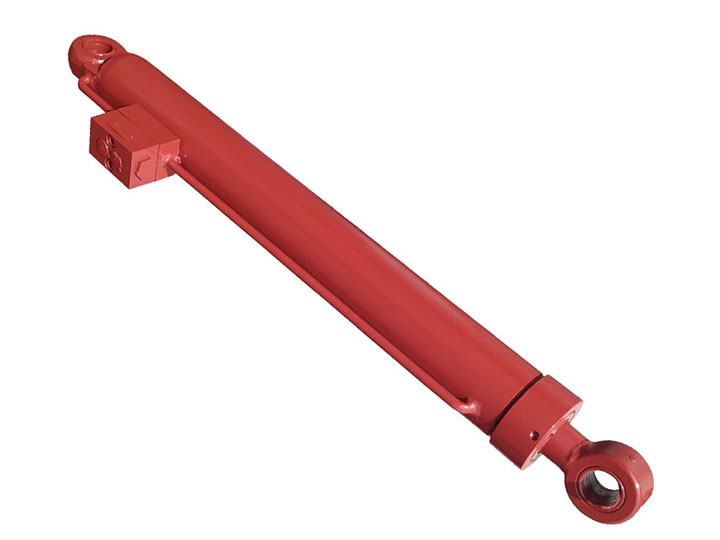

Hungary hydraulic cylinder,pipe bender hydraulic cylinder manufacturer,pipe bender hydraulic cylinder

(Hungary pipe bender hydraulic cylinder,produced by Hengyu Hydraulic Co., Ltd)

pipe bender hydraulic cylinder are widely used in Hungary,because of long service life,smooth movement,high work efficiency.So our company has designed pipe bender hydraulic cylinder for customers from Hungary.

Regular maintenance of the pipe bender hydraulic cylinder includes: regular tightening, pipe bender hydraulic cylinder fastening screws and gland screws, pipe bender hydraulic cylinder piston rod stop adjustment screws, should be tightened once a month, tighten each screw evenly, and achieve the corresponding tightening torque. Replace the seal regularly, it is recommended to replace the seal of the pipe bender hydraulic cylinder once a year. Clean regularly, the pipe bender hydraulic cylinder is cleaned every other year, and the seals are replaced while cleaning.

If the pipe bender hydraulic cylinder operation failure, you can start from these aspects to troubleshoot: (1) the hydraulic system control pressure is too low. The throttling resistance in the control line may be too large, the flow valve is improperly adjusted, the control pressure is inappropriate, and the pressure source is disturbed. At this time, the control pressure source should be checked to ensure that the pressure is adjusted to the specified value of the system; (2) Air enters the hydraulic system. Mainly because there is a leak in the system. At this time, check the liquid level of the hydraulic tank, the seals and fittings on the oil suction side of the hydraulic pump, and whether the oil suction filter is too dirty. If so, the hydraulic oil should be replenished, seals and fittings should be treated, and the coarse filter element should be cleaned or replaced. (3) The initial action of the pipe bender hydraulic cylinder is slow. In the case of low temperature, the hydraulic oil viscosity is large, poor flow, resulting in slow pipe bender hydraulic cylinder action. The improvement method is to replace the hydraulic oil with better viscosity and temperature performance If the pipe bender hydraulic cylinder is weak and cannot push the load, please check the internal leakage problem. The internal leakage of the pipe bender hydraulic cylinder includes the leakage caused by excessive wear of the pipe bender hydraulic cylinder block seal, the piston rod and the seal cover seal and the piston seal. The cause of sealing leakage between the piston rod and the seal cover is that the seal is wrinkled, squeezed, torn, worn, aging, deterioration, deformation, etc., and a new seal should be replaced at this time. The main cause of excessive piston seal wear is improper adjustment of the speed control valve, resulting in excessive back pressure and improper seal installation or hydraulic oil contamination. The second is that foreign bodies enter the assembly and the quality of sealing materials is not good. The result is that the action is slow and weak, and in serious cases, it will cause damage to the piston and pipe bender hydraulic cylinder, and the phenomenon of "pulling the pipe bender hydraulic cylinder" appears. The treatment method is to adjust the speed control valve, and the necessary operations should be done according to the installation instructions.

pipe bender hydraulic cylinder can not drive the load troubleshooting: oil pressure is too low. pipe bender hydraulic cylinder selection specifications are too small. Leakage in pipe bender hydraulic cylinder or associated hydraulic system element.

The assembly work of the pipe bender hydraulic cylinder has a great impact on the quality of the pipe bender hydraulic cylinder: each part must be carefully cleaned before assembly; To correctly install the sealing device everywhere: when installing the sealing ring, pay attention to its installation direction to avoid oil leakage due to installation, and its lip should be equipped with a pressure oil chamber. In addition, because it is a YX-shaped sealing ring, it is necessary to pay attention to distinguish between shaft and hole use, do not install wrong; Because the sealing device is matched with the sliding surface, an appropriate amount of hydraulic oil should be applied during assembly; The special wrench should be used when the threaded coupling is tightened, and the torque should meet the standard requirements; After the piston and piston rod are assembled, it is necessary to measure whether the coaxiality and straightness on the full length are out of whack. After assembly, there should be no blocking sensation and uneven resistance when the piston assembly moves.

How do hydraulic equipment and hydraulic cylinders maintain a certain pressure after pressing to a certain position?

There are several methods. 1. You can use a constant pressure variable pump to adjust the control pressure of the pump to the pressure required by the cylinder, so that when the cylinder is in place, the pump uses the minimum flow rate to maintain the pressure, and the system is more energy saving. 2. If the pressure is maintained for a short time, a hydraulic control check valve can be added to the oil inlet end of the cylinder to close the cylinder and maintain the pressure. If the volume of the cylinder is large, an accumulator can be added between the valve and the cylinder to maintain pressure for 10-30 minutes. 3. You can add a small flow pump, the large pump after unloading, the small pump has been running, specifically for maintaining pressure.

What is the HS code of the hydraulic cylinder?

HS code of hydraulic cylinder; 8412210000 8412210000 Linear hydraulic power unit (hydraulic cylinder) 0.12000 0.35000 0.00000 0.17000 0.00000