Release time:2023-11-30 11:00:10 Hits: Current position: Home > News

This article mainly introduces:

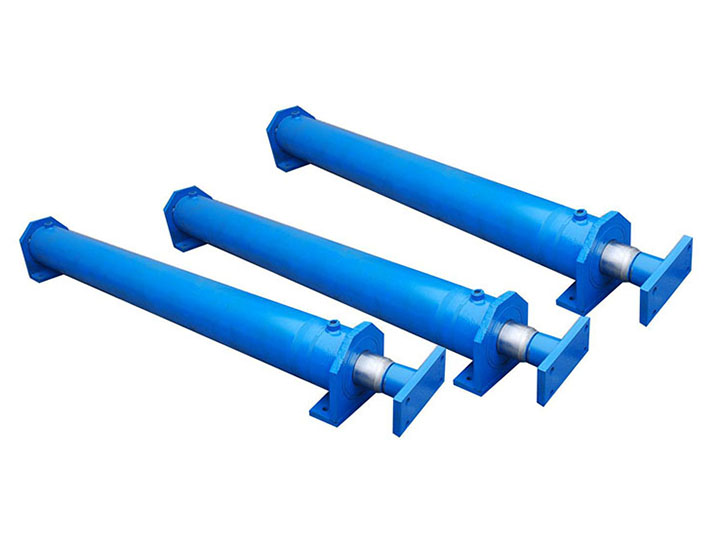

Canada hydraulic cylinder,push and pull the cylinder manufacturer,push and pull the cylinder

(Canada push and pull the cylinder,produced by Hengyu Group)

push and pull the cylinder are widely used in Canada,because of clever hydraulic energy conversion,high work efficiency,excellent fatigue and impact resistance.So our company has designed push and pull the cylinder for customers from Canada.

The body of the push and pull the cylinder on the processing process requirements: the body of the push and pull the cylinder is an important and essential part of the push and pull the cylinder, because it has an irreplaceable role. The processing requirements for this part are very high, requiring that the surface roughness of the push and pull the cylinder after processing should reach 0.4-0.8um, and the coaxiality and wear resistance requirements are also very high.

The assembly work of the push and pull the cylinder has a great impact on the quality of the push and pull the cylinder: each part must be carefully cleaned before assembly; To correctly install the sealing device everywhere: when installing the sealing ring, pay attention to its installation direction to avoid oil leakage due to installation, and its lip should be equipped with a pressure oil chamber. In addition, because it is a YX-shaped sealing ring, it is necessary to pay attention to distinguish between shaft and hole use, do not install wrong; Because the sealing device is matched with the sliding surface, an appropriate amount of hydraulic oil should be applied during assembly; The special wrench should be used when the threaded coupling is tightened, and the torque should meet the standard requirements; After the piston and piston rod are assembled, it is necessary to measure whether the coaxiality and straightness on the full length are out of whack. After assembly, there should be no blocking sensation and uneven resistance when the piston assembly moves.

In the case of serious wear on the inner surface of the push and pull the cylinder, or when there is a deep longitudinal tensile mark, it should be mapped according to the physical object and re-produced by the professional manufacturer according to the push and pull the cylinder manufacturing process for replacement. The push and pull the cylinder can also be repaired with TS311 antiwear repair agent. TS311 anti-wear repair agent is mainly used for the repair of worn and slipped metal parts.

Most of the failure of the push and pull the cylinder is because there is a foreign body in the push and pull the cylinder into the failure of the push and pull the cylinder, the most problematic is that it is difficult to determine when the foreign body is into the push and pull the cylinder. After a foreign body enters, if the outer side of the sliding surface of the piston is equipped with a seal with a lip edge, then the lip edge of the seal can scrape the foreign body when working, which is beneficial to avoid scratching. However, the piston equipped with 0-shaped sealing ring has a sliding surface at both ends, and foreign bodies are sandwiched between this sliding surface, which is easy to form scars.

How to calculate hydraulic cylinder thrust?

Cylinder diameter = piston diameter =200MM Piston area =π (200/2) square =3140 square mm =31.4 square cm 25MPA=250KG/ square cm Maximum thrust = pressure * Piston area =250 *31.4 =7850KG=78500 Newtons This is the maximum thrust. The formula can be derived from the calculation formula.

What should we pay attention to when using the cylinder?

When using the cylinder, we should pay attention to the environment and temperature in which it is located as follows: 1. Before working, the hydraulic cylinder must carry out several reciprocating movements under low pressure (greater than the starting pressure), and work normally after removing the gas in the cylinder. 2. Precautions when removing the hydraulic cylinder: ① The pressure in the hydraulic circuit is reduced to zero before disassembly. ② The screw thread at the top of the piston rod should be prevented from damage when disassembling. ③ Due to the different structure and size of the hydraulic cylinder, the order of disassembly is also slightly different. Generally, the fastening bolt of the end cover should be loosened first. Internal card chain card key application special tools.