Release time:2023-11-28 10:55:35 Hits: Current position: Home > News

This article mainly introduces:

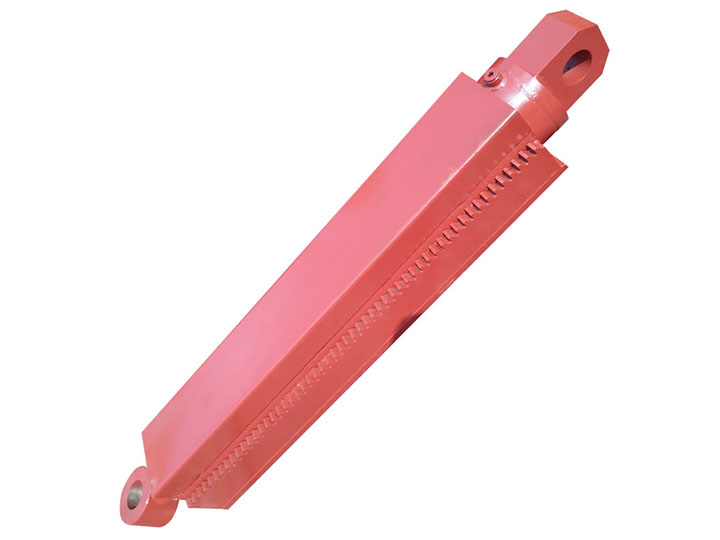

Paraguay hydraulic cylinder,single rack cylinder manufacturer,single rack cylinder

(Paraguay single rack cylinder,produced by Hengyu Hydraulic Co., Ltd)

single rack cylinder are widely used in Paraguay,because of smooth movement,high work efficiency,excellent fatigue and impact resistance.So our company has designed single rack cylinder for customers from Paraguay.

The single rack cylinder is a hydraulic actuator that converts hydraulic energy into mechanical energy and does linear reciprocating motion (or swinging motion). It is simple in structure and reliable in operation. When it is used to achieve reciprocating movement, the deceleration device can be eliminated, and there is no transmission gap, and the movement is smooth, so it is widely used in various mechanical hydraulic systems. The output force of the single rack cylinder is proportional to the effective area of the piston and the pressure difference between the two sides; The single rack cylinder is basically composed of single rack cylinder and single rack cylinder head, piston and piston rod, sealing device, buffer device and exhaust device. Buffer device and exhaust device depending on the specific application, other devices are essential.

When the single rack cylinder is customized, if there are high requirements for the quality of the single rack cylinder, it is best to use rolling processing, because the surface layer has surface residual compressive stress, which helps to close the surface of the small crack, preventing the expansion of erosion. Thus, the corrosion resistance of the surface can be improved, and the fatigue crack can be delayed or expanded, and the fatigue strength of the single rack cylinder can be improved. By rolling forming, a cold working hardening layer is formed on the rolling surface, which reduces the elastic and plastic deformation of the contact surface of the grinding pair, thereby improving the wear resistance of the inner wall of the single rack cylinder and avoiding the burn caused by grinding. After rolling, the reduction of surface roughness value can improve the matching property.

The difference between the integral single rack cylinder and the split single rack cylinder: The integral single rack cylinder and the split single rack cylinder in the single rack cylinder are two different single rack cylinders, and they are very different. The whole single rack cylinder, which is cast in one body, is not prone to problems such as oil leakage; The split single rack cylinder is welded twice, so if it is not handled well at the welding, it is prone to problems such as oil leakage and single rack cylinder damage. Therefore, it is obvious that the answer to this question is for difference.

When installing the piston rod, it is necessary to ensure that the direction of the connecting head at the top of the piston rod should be consistent with the direction of the single rack cylinder head adn the earring (or the middle hinge shaft), and ensure the straightness of the whole piston rod during the advance and return process to prevent the phenomenon of rigid interference and causing unnecessary damage.

How to calculate the speed of cylinder weight decline?

To reduce the weight of the cylinder, the necessary condition is that the weight of the piston rod + external load is greater than the friction between the seal ring and the cylinder. There are many reasons for this, first of all, consider the reasons of the cylinder itself, the piston in the cylinder and the sealing ring on the piston rod will play a reaction force on the weight of the cylinder (because of friction), which depends on the tightness of the sealing ring and the cylinder. Secondly, what is connected under the piston rod of the cylinder and how much weight there is. And the way the cylinders are arranged, is it completely vertical. Anyway, in fact, the most important thing is to see how much the bore of the oil hole of the piston rod cavity of your cylinder is. For example, if the hole in the lower chamber of the cylinder is small, as thin as a needle, then its descent rate will be slow.

Two cylinders in parallel, how to solve the synchronization problem?

The following methods can be used to achieve parallel cylinder synchronization: 1, rigid mechanical synchronization. 2. The throttle valve or speed regulating valve is used in the circuit to adjust the synchronization. 3, the two cylinders use independent quantitative pump oil supply to achieve synchronization. 4. Synchronous motor is used in the loop to realize cylinder synchronization. 5, using the position sensor to measure the stroke position and control the cylinder synchronization through the electrical system.