Release time:2023-11-27 15:08:56 Hits: Current position: Home > News

This article mainly introduces:

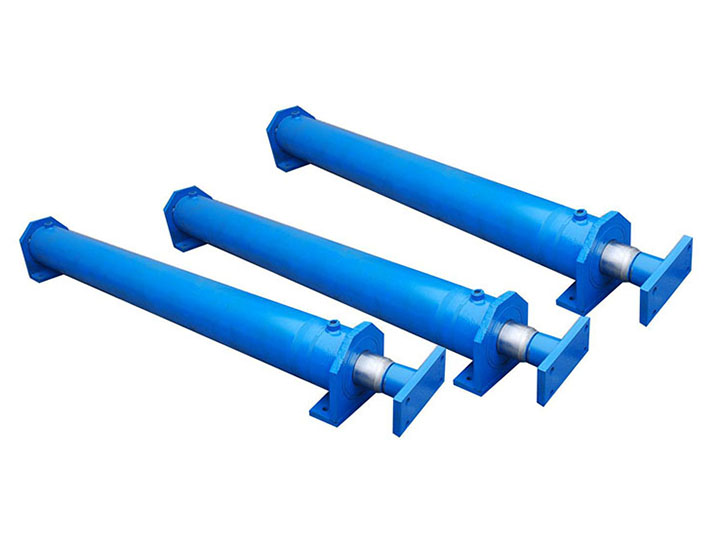

Congo hydraulic cylinder,push and pull the cylinder manufacturer,push and pull the cylinder

(Congo push and pull the cylinder,produced by Hengyu Group)

push and pull the cylinder are widely used in Congo,because of clever hydraulic energy conversion,simple structure and reliable operation,excellent temperature resistance.So our company has designed push and pull the cylinder for customers from Congo.

After chrome plating of the piston rod of the push and pull the cylinder, the surface flatness is not fully treated: After chrome plating of the piston rod surface, the method of post-plating polishing should be changed to post-plating polishing. Although it is necessary to increase the thickness of the coating before grinding (generally increased by about 0.02 in the diameter direction), it can remove chrome plating defects well, and test the binding force of the coating. In addition, due to the micro-roughness of the grinding surface, the trough can store lubricating oil, which can improve the wear resistance and extend the service life.

push and pull the cylinder body inspection: The inner surface of the push and pull the cylinder and the piston seal are the main factors causing the leakage in the push and pull the cylinder, if the push and pull the cylinder has a longitudinal tensile mark, even if the new piston seal is replaced, it can not effectively eliminate the fault, the inner surface of the push and pull the cylinder mainly checks whether the dimensional tolerance and shape and position tolerance meet the technical requirements, there is no longitudinal tensile mark, and measures the depth of the longitudinal tensile mark, in order to take the corresponding solution.

If it is found that the push and pull the cylinder lubrication is poor or the push and pull the cylinder bore processing is abnormal, it is necessary to feedback the situation to the manufacturer, because the piston and the push and pull the cylinder, the guide rail and the piston rod have relative movement, if the lubrication is poor or the push and pull the cylinder bore is abnormal, it will aggravate the wear and reduce the straightness of the push and pull the cylinder center line. In this way, when the piston works in the push and pull the cylinder, the friction resistance will be large and small, resulting in slip or crawling. The solution is to repair and grind the push and pull the cylinder first, and then prepare the piston according to the matching requirements, repair and grind the piston rod, and configure the guide sleeve.

The piston seal of the push and pull the cylinder is the main element to prevent leakage in the push and pull the cylinder. For the lip seal, it should focus on checking whether the lip edge is bruised and worn, and for the combination seal, it should focus on checking the wear of the sealing surface, and then determine whether the seal can be used. In addition, it is necessary to check whether the static seal between the piston and the piston rod is crushed. The piston rod seal should focus on checking the wear of the seals and supporting rings.

How to deal with hydraulic cylinder inner wall rag, local wear serious or corrosion?

It can be reparied if the inner wall of the hydraulic cylinder is frayed, local wear or corrosion. We can use the inner wall cold melting copper technology, it has the following advantages: first, the temperature is low, the operating temperature is less than 180 degrees, and the heat affected zone is small. Second: high hardness is up to Brinell hardness 280, wear resistance and anti-corrosion. Third: the process is mature, some large coal mills have been repaired with this method and the effect is remarkable.

What is the difference between hydraulic piston cylinder and plunger cylinder?

The force surface of the piston cylinder is a rod cavity and a rodless cavity, and the force surface of the plunger cylinder is the plunger, the spring return single-acting piston cylinder can also rely on the external force of the spring to achieve return, the double-acting piston cylinder can produce tension, and the plunger cylinder only produces thrust without tension.