Release time:2023-11-20 09:49:48 Hits: Current position: Home > News

This article mainly introduces:

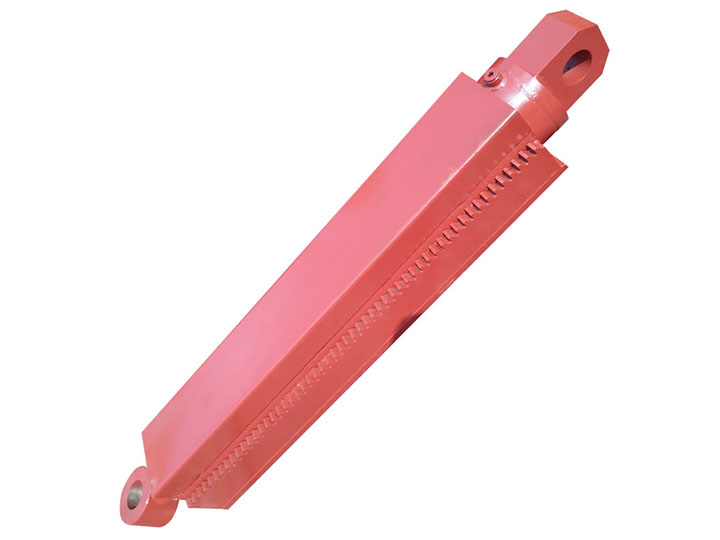

The Philippines hydraulic cylinder,single rack cylinder manufacturer,single rack cylinder

(The Philippines single rack cylinder,produced by Hengyu Hydraulic Cylinder Factory)

single rack cylinder are widely used in The Philippines,because of excellent fatigue and impact resistance,no need for deceleration device,long service life.So our company has designed single rack cylinder for customers from The Philippines.

What kind of process is used in the single rack cylinder to make high-quality single rack cylinder products: the body is the main component of the single rack cylinder, mining single pillar, hydraulic support, gun tube and other products, and its processing quality directly affects the life and reliability of the entire product. Body processing requirements are high, the internal surface roughness requirements are Ra0.4 ~ 0.8&um, the coaxiality, wear resistance requirements are strict. The basic feature of body is deep hole processing, which has always troubled the processing personnel. The single rack cylinder products of our company mainly use rolling processing, because the surface layer has surface residual compressive stress, which helps to close the surface micro-cracks and hinder the expansion of erosion. Thus, the corrosion resistance of the surface can be improved, and the fatigue crack can be delayed or expanded, and the fatigue strength of the body can be improved. The correct rolling process of the single rack cylinder block: broaching block - fine boring block - grinding block. The rolling method is: broaching block - fine boring block - rolling block, the process is 3 parts, but the time is compared: grinding 1 meter of the block is about 1-2 days, rolling 1 meter of the block is about 10-30 minutes. Input comparison: grinding machine or quilting machine (tens of thousands - millions), rolling knife (ten thousand - tens of thousands). After rolling, the surface roughness of the hole decreases from RA3.2-6.3um before rolling to RA0.4-0.8&um, the surface hardness of the hole increases by about 30%, and the fatigue strength of the inner surface of the single rack cylinder increases by 25%. If the service life of the single rack cylinder is only considered, it is increased by 2 to 3 times, and the efficiency of the boring and rolling process is about 3 times higher than that of the grinding process. single rack cylinder misoperation or operation failure may be caused by the following reasons, you can start from these aspects of the investigation: (1) spool stuck or valve hole blocked. When the spool of the flow valve or direction valve is stuck or the valve hole is blocked, the single rack cylinder is prone to misoperation or operation failure. At this time, the contamination of the oil should be checked; Check whether dirt or colloidal deposits are stuck in the spool or blocking the valve hole; Check the wear of the valve body, clean and replace the system filter, clean the fuel tank, and replace the hydraulic medium. (2) The piston rod and single rack cylinder are stuck or the single rack cylinder is blocked. At this time, no matter how to manipulate, the single rack cylinder does not move or moves very little. At this time, check whether the piston and piston rod seal is too tight, whether it enters the dirt and gum deposits: whether the shaft line of the piston rod and the single rack cylinder is in the center, whether the wearing parts and seals are invalid, and whether the load is too large.

The machining accuracy of the single rack cylinder depends on the level of equipment, production technology and testing means. single rack cylinder processing methods are commonly used in two ways, one is rough boring - fine boring - rolling, generally with 45# seamless steel pipe, this method of processing quality is good, but the cost is high. Another method is to use 20# cold-drawn seamless steel pipe, and then honing, the cost is lower. The piston rod must be adjusted and straightened before processing, and the coating thickness of the piston rod is generally not less than 0.03mm. The piston must be machined in strict accordance with the groove size and tolerance requirements given in the seal manual.

When the single rack cylinder is installed, the piston and the single rack cylinder head and other parts have large mass, large size and large inertia, even if there is a lifting equipment auxiliary installation, because the specified clearance is small, no matter how hard it will be put into, therefore, the end of the piston or the single rack cylinder head boss is easy to cause scars when it hits the inner surface of the single rack cylinder wall. The solution to this problem: for a large number of small products, the use of autocratic assembly oriented tools during installation; For heavy, thick and large large and medium-sized single rack cylinders, only careful and careful operation can be avoided.

The pressure, temperature, medium and speed of different types of seals are not the same, water-ethylene glycol medium (HFC) can not be sealed with polyurethane, it can only use rubber seal; When the single rack cylinder is running fast, it must be sealed with slip ring, such as Sterseal, Glairing, GD1000K, TDI, etc., when the running speed is slow, Yx, U, V combination seals can be used; Fluorine rubber seal is used in high temperature and high pressure environment; When the running speed is fast, the buffer sleeve and buffer valve must be considered.

Why the lifting cylinder falling by itself?

May be there is a pressure relief point. Check and repair the following parts: whether there is oil leakage in the transparent pipe at the top of the cylinder: the cylinder oil seal is broken, and the cylinder and oil seal need to be replaced; No: The multiway valve has pressure relief and needs to be repaired. Maintenance in accordance with routine maintenance items can reduce mechanical failures: 1. Check whether the thermostat works normally. 2, check the transmission shift work is normal. 3. Check the tightness of the fan belt. 4, check whether the diesel tank oil inlet filter is blocked or damaged, and clean or replace the filter. 5. Check and adjust the valve clearance.

Classification and application of cylinders.

Hydraulic cylinder is divided into single acting hydraulic cylinder, double acting cylinder, combined hydraulic cylinder, swing hydraulic cylinder. Single acting cylinder is divided into plunger type hydraulic cylinder, single piston rod hydraulic cylinder, double piston rod hydraulic cylinder, telescopic hydraulic cylinder. Plunger type hydraulic cylinder: the plunger moves only in one direction, and the return stroke is to push the plunger back using its own weight or load. Single piston rod hydraulic cylinder: The piston moves only in one direction, and the return stroke is to push the plunger back using dead weight or load. Double piston rod hydraulic cylinder: both sides of the piston are equipped with piston rods, and pressure oil can only be supplied to one side of the piston. The return stroke usually uses spring force, gravity or external force. Telescopic hydraulic cylinder: It obtains long stroke with short cylinder. The hydraulic oil is pushed out from large to small section by section, and the external force is reduced from small to large.