Release time:2023-11-19 14:06:10 Hits: Current position: Home > News

This article mainly introduces:

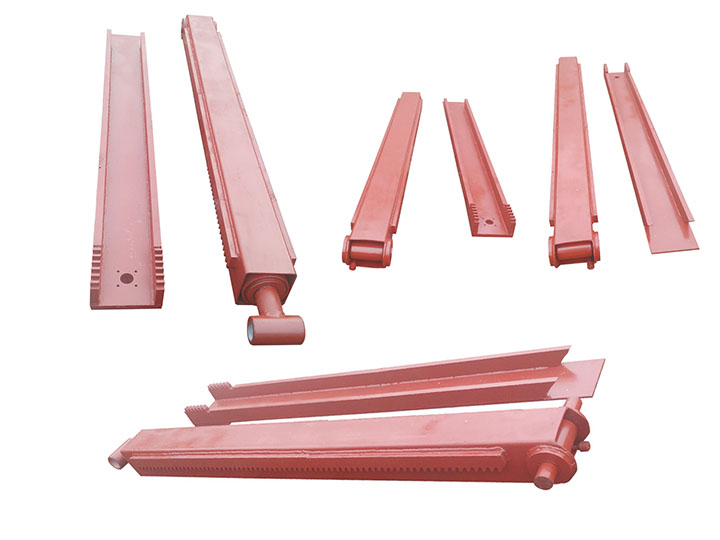

New Zealand hydraulic cylinder,rack cylinder manufacturer,rack cylinder

(New Zealand rack cylinder,produced by Hengyu Group)

rack cylinder are widely used in New Zealand,because of excellent temperature resistance,no transmission clearance,powerful torque.So our company has designed rack cylinder for customers from New Zealand.

Factors that should be considered when selecting the oil seal in the rack cylinder: some specific factors should be taken into account when selecting the oil seal in the rack cylinder, so as to have correct consideration and get accurate results, and then avoid wrong selection. The factors and aspects that should be taken into account are eight: rack cylinder diameter, piston rod diameter, piston rod and piston groove size, rack cylinder working pressure, rack cylinder movement speed, hydraulic system oil temperature and rack cylinder working environment.

In order to ensure the service life of the rack cylinder, the hydraulic system must be set up effective filtration to prevent pollution, the cleanliness of the oil should meet the ISO4406 standard, and the quality of the filtration should also meet the corresponding standards in ISO. The grade requirements of the filter are performed according to the actual working conditions of the system, but the minimum requirements are not less than 19/15 in ISO4406, that is, 24μ (β10≥75) in ISO4572.

When the rack cylinder is installed, the piston and the rack cylinder head and other parts have large mass, large size and large inertia, even if there is a lifting equipment auxiliary installation, because the specified clearance is small, no matter how hard it will be put into, therefore, the end of the piston or the rack cylinder head boss is easy to cause scars when it hits the inner surface of the rack cylinder wall. The solution to this problem: for a large number of small products, the use of autocratic assembly oriented tools during installation; For heavy, thick and large large and medium-sized rack cylinders, only careful and careful operation can be avoided.

1, the hydraulic machinery should be kept clean, in order to prevent dust and debris from falling into the oil, the tank should be sealed. 2, the oil in the tank should be replaced regularly according to the working condition. When changing the oil, the dirt and impurities accumulated at the bottom of the tank should be removed and the tank should be cleaned. 3, hydraulic oil, oil drums should be set in a clean and safe place to strengthen management. The oil drum, oil filter, oil funnel, oil pipe, etc. used should be kept clean. The oil drums for loading hydraulic oil must be cleaned in advance, and the oil drums should be dedicated and not mixed with other oil drums.

Why does the hydraulic cylinder rebound after the rod cavity is extended into place?

The reason is that after the rod cavity is extended into place, the rod cavity and the rodless cavity are connected, so that the cylinder moves towards the rod cavity. After connecting, it is equivalent to the hydraulic oil directly driving the cylinder with an area equal to the piston rod. After the end of this problem, it is estimated that the seal is not very good, and the two cavities are connected after the pressure is increased to a certain extent; Or there is a problem in the valve, so that the two chambers are connected after reaching a certain pressure. Other phenomena: If the load is increased to a certain extent, no matter which side of the solenoid valve is energized, the cylinder will move to the rod cavity.

Two cylinders in parallel, how to solve the synchronization problem?

The following methods can be used to achieve parallel cylinder synchronization: 1, rigid mechanical synchronization. 2. The throttle valve or speed regulating valve is used in the circuit to adjust the synchronization. 3, the two cylinders use independent quantitative pump oil supply to achieve synchronization. 4. Synchronous motor is used in the loop to realize cylinder synchronization. 5, using the position sensor to measure the stroke position and control the cylinder synchronization through the electrical system.