Release time:2023-11-18 17:15:53 Hits: Current position: Home > News

This article mainly introduces:

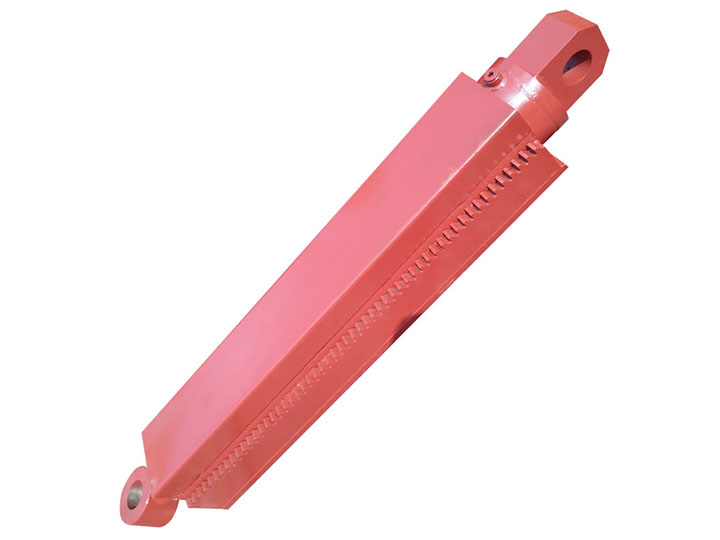

Holland hydraulic cylinder,single rack cylinder manufacturer,single rack cylinder

(Holland single rack cylinder,produced by Hengyu Group)

single rack cylinder are widely used in Holland,because of excellent fatigue and impact resistance,smooth movement,high work efficiency.So our company has designed single rack cylinder for customers from Holland.

single rack cylinders in series, parallel and series parallel. Series: In the single rack cylinder, the oil inlet of the subsequent reversing valve is the supply of the previous oil return, and there is no separate oil return circuit connected with the oil return in each valve. Series: In the single rack cylinder, the oil inlet of the subsequent reversing valve is the supply of the previous oil return, and there is no separate oil return circuit connected with the oil return in each valve. Parallel: the pressure oil in the single rack cylinder is connected with the inlet oil of each reversing valve, and the return oil is collected by the return oil circuit. Series parallel: For this one, compared with the simple series and parallel, it is slightly more complicated, but it is not impossible to understand. The series refers to the oil in the single rack cylinder, which is in series form, but can not form a series circuit, and the parallel refers to the oil return circuit of each valve, which is in parallel.

The coordination of the sliding parts of the single rack cylinder itself should not be too tight, the sealing friction force should not be too large, and H8 / f8 coordination should be selected between the piston rod and the guide sleeve; Check whether the size of the sealing ring is processed strictly according to the standard; If the V-shaped sealing ring is used, the sealing friction should be adjusted to a moderate degree.

The assembly work of the single rack cylinder has a great impact on the quality of the single rack cylinder: each part must be carefully cleaned before assembly; To correctly install the sealing device everywhere: when installing the sealing ring, pay attention to its installation direction to avoid oil leakage due to installation, and its lip should be equipped with a pressure oil chamber. In addition, because it is a YX-shaped sealing ring, it is necessary to pay attention to distinguish between shaft and hole use, do not install wrong; Because the sealing device is matched with the sliding surface, an appropriate amount of hydraulic oil should be applied during assembly; The special wrench should be used when the threaded coupling is tightened, and the torque should meet the standard requirements; After the piston and piston rod are assembled, it is necessary to measure whether the coaxiality and straightness on the full length are out of whack. After assembly, there should be no blocking sensation and uneven resistance when the piston assembly moves.

If it is found that the single rack cylinder lubrication is poor or the single rack cylinder bore processing is abnormal, it is necessary to feedback the situation to the manufacturer, because the piston and the single rack cylinder, the guide rail and the piston rod have relative movement, if the lubrication is poor or the single rack cylinder bore is abnormal, it will aggravate the wear and reduce the straightness of the single rack cylinder center line. In this way, when the piston works in the single rack cylinder, the friction resistance will be large and small, resulting in slip or crawling. The solution is to repair and grind the single rack cylinder first, and then prepare the piston according to the matching requirements, repair and grind the piston rod, and configure the guide sleeve.

What are the requirements for hydraulic cylinder assembly? ① The installation of the cylinder should be solid and reliable. In order to prevent the influence of thermal expansion, in the case of large stroke and hot working conditions, one end of the cylinder must be kept floating.② pipe connection shall not be relaxed.③ The mounting surface of the hydraulic cylinder and the sliding surface of the piston rod should maintain sufficient parallelism and perpendicality.④ The central axis of the moving cylinder should be concentric with the center line of the load force, otherwise it will cause lateral force, which is easy to wear the seal And piston damage. The greater the distance between the supporting points of the piston rod, the smaller its wear. For the hydraulic cylinder of the moving object, the installation should keep the cylinder parallel with the moving object, and the degree of non-parallelism is generally not greater than 0.05mm/m. ⑤The sealing ring should not be installed too tightly, especially the U-shaped sealing ring.

How to calculate the speed of cylinder weight decline?

To reduce the weight of the cylinder, the necessary condition is that the weight of the piston rod + external load is greater than the friction between the seal ring and the cylinder. There are many reasons for this, first of all, consider the reasons of the cylinder itself, the piston in the cylinder and the sealing ring on the piston rod will play a reaction force on the weight of the cylinder (because of friction), which depends on the tightness of the sealing ring and the cylinder. Secondly, what is connected under the piston rod of the cylinder and how much weight there is. And the way the cylinders are arranged, is it completely vertical. Anyway, in fact, the most important thing is to see how much the bore of the oil hole of the piston rod cavity of your cylinder is. For example, if the hole in the lower chamber of the cylinder is small, as thin as a needle, then its descent rate will be slow.