Release time:2023-11-17 13:21:17 Hits: Current position: Home > News

This article mainly introduces:

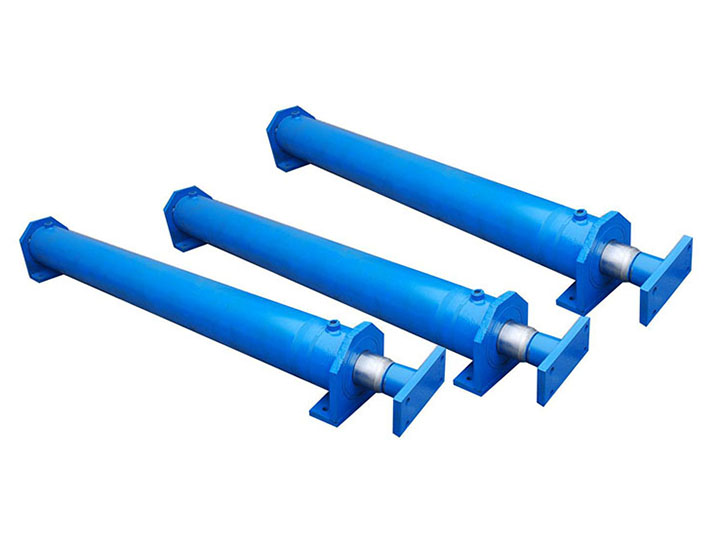

Bulgaria hydraulic cylinder,push and pull the cylinder manufacturer,push and pull the cylinder

(Bulgaria push and pull the cylinder,produced by Hengyu Hydraulic Co., Ltd)

push and pull the cylinder are widely used in Bulgaria,because of clever hydraulic energy conversion,clever hydraulic energy conversion,simple structure and reliable operation.So our company has designed push and pull the cylinder for customers from Bulgaria.

When purchasing the push and pull the cylinder, try to clarify the following parameters of the push and pull the cylinder: A. push and pull the cylinder diameter, rod diameter, stroke; B. Working pressure or push and pull the cylinder load; C. Working environment temperature; D. Working medium; E. Operating speed; F. Other parameters, such as connection form, mounting size, etc. In this way, the right push and pull the cylinder type can be found accurately and quickly.

The push and pull the cylinder should be avoided for a long time without use, if it is indeed idle for a long time for some reason, it should also be regularly turned on for empty operation, so that its parts can be fully lubricated, so as to avoid rust on the working surface and affect the normal work in the future. (If it cannot be turned on and run, a small amount of lubricating oil can be applied on its outer surface for protection) ' The use of the push and pull the cylinder should pay attention to: the operation should be as far away from the push and pull the cylinder as possible, to avoid falling objects, knocking, rubbing the push and pull the cylinder coating. When cleaning the push and pull the cylinder, only use soft materials (such as cotton) to wipe, and do not scratch high-hardness materials. Do not use the push and pull the cylinder when the oil temperature exceeds 70 ° C.

Before purchasing the push and pull the cylinder, it is necessary to master the original information and design basis, mainly including: the use and working conditions of the machine; The structural characteristics, load conditions, stroke size and operation requirements of the working mechanism; The selected working pressure and flow of the hydraulic system; The reality of materials, fittings and processes; Relevant national standards and technical specifications, etc.

The commonly used buffer structure of the push and pull the cylinder is composed of a piston boss and a push and pull the cylinder head groove. When the piston moves close to the push and pull the cylinder head, it gradually enters the groove, and the oil in the groove is extruded through the gap between the boss and the groove, which increases the oil return resistance, produces the braking effect and realizes the buffer. Generally, a buffer mechanism should be used when the pressure is above 10MP.

What are the functions of hydraulic cylinders?

Hydraulic cylinder is a hydraulic actuator, the specific role depends on the installation occasion and the type of hydraulic cylinder. Hydraulic cylinder is mainly used in machinery, and it is the most important component of construction machinery. It is important core component which mainly provide power for machinery.

What are the requirements for hydraulic cylinder assembly? ① The installation of the cylinder should be solid and reliable. In order to prevent the influence of thermal expansion, in the case of large stroke and hot working conditions, one end of the cylinder must be kept floating.② pipe connection shall not be relaxed.③ The mounting surface of the hydraulic cylinder and the sliding surface of the piston rod should maintain sufficient parallelism and perpendicality.④ The central axis of the moving cylinder should be concentric with the center line of the load force, otherwise it will cause lateral force, which is easy to wear the seal And piston damage. The greater the distance between the supporting points of the piston rod, the smaller its wear. For the hydraulic cylinder of the moving object, the installation should keep the cylinder parallel with the moving object, and the degree of non-parallelism is generally not greater than 0.05mm/m. ⑤The sealing ring should not be installed too tightly, especially the U-shaped sealing ring.