This article mainly introduces:

Oman hydraulic cylinder,rack cylinder manufacturer,rack cylinder

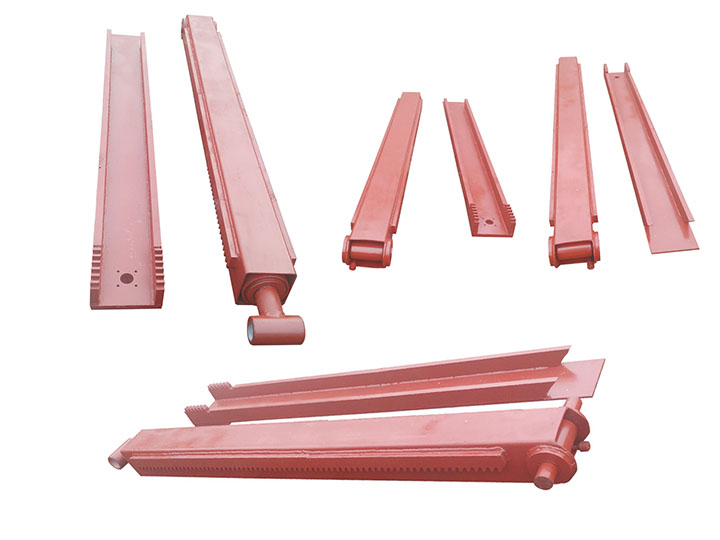

(Oman rack cylinder,produced by Hengyu Group)

rack cylinder are widely used in Oman,because of no transmission clearance,powerful torque,clever hydraulic energy conversion.So our company has designed rack cylinder for customers from Oman.

When the rack cylinder wear is serious, you can try to use an alloy scraper to shave grooves with a depth of more than 1mm on the surface of the slip injury, then clean the grooves with acetone, apply the adjusted TS311 anti-wear repair agent on the polished surface with the rack cylinder inner diameter copying plate, and scrape it flat vigorously to ensure compaction and higher than the inner surface of the rack cylinder. After curing, polish to leave a finishing margin. Finally, the overall size, shape tolerance and roughness of the rack cylinder can meet the requirements by grinding. However, the life and reliability of this repair rack cylinder are not high.

rack cylinder to reasonable use of hydraulic oil: strict hydraulic oil selection off. Hydraulic oil is selected in strict accordance with oil standards. The selection of good quality hydraulic oil can effectively prevent bubbles in the working process of the hydraulic system. When choosing the oil, it should be selected according to the lowest temperature in different regions, and fill the hydraulic oil according to the dipstick standard, and at the same time, it should also keep the hydraulic system clean (when filling the hydraulic oil, it should prevent the water and other impurities into it), and often check the oil quality, oil level and oil color of the hydraulic oil. If blisters and bubbles are found in the hydraulic oil. When the oil becomes milky white, the source of the air in the oil should be carefully found and eliminated in time.

What kind of process is used in the rack cylinder to make high-quality rack cylinder products: the body is the main component of the rack cylinder, mining single pillar, hydraulic support, gun tube and other products, and its processing quality directly affects the life and reliability of the entire product. Body processing requirements are high, the internal surface roughness requirements are Ra0.4 ~ 0.8&um, the coaxiality, wear resistance requirements are strict. The basic feature of body is deep hole processing, which has always troubled the processing personnel. The rack cylinder products of our company mainly use rolling processing, because the surface layer has surface residual compressive stress, which helps to close the surface micro-cracks and hinder the expansion of erosion. Thus, the corrosion resistance of the surface can be improved, and the fatigue crack can be delayed or expanded, and the fatigue strength of the body can be improved. The correct rolling process of the rack cylinder block: broaching block - fine boring block - grinding block. The rolling method is: broaching block - fine boring block - rolling block, the process is 3 parts, but the time is compared: grinding 1 meter of the block is about 1-2 days, rolling 1 meter of the block is about 10-30 minutes. Input comparison: grinding machine or quilting machine (tens of thousands - millions), rolling knife (ten thousand - tens of thousands). After rolling, the surface roughness of the hole decreases from RA3.2-6.3um before rolling to RA0.4-0.8&um, the surface hardness of the hole increases by about 30%, and the fatigue strength of the inner surface of the rack cylinder increases by 25%. If the service life of the rack cylinder is only considered, it is increased by 2 to 3 times, and the efficiency of the boring and rolling process is about 3 times higher than that of the grinding process. rack cylinder misoperation or operation failure may be caused by the following reasons, you can start from these aspects of the investigation: (1) spool stuck or valve hole blocked. When the spool of the flow valve or direction valve is stuck or the valve hole is blocked, the rack cylinder is prone to misoperation or operation failure. At this time, the contamination of the oil should be checked; Check whether dirt or colloidal deposits are stuck in the spool or blocking the valve hole; Check the wear of the valve body, clean and replace the system filter, clean the fuel tank, and replace the hydraulic medium. (2) The piston rod and rack cylinder are stuck or the rack cylinder is blocked. At this time, no matter how to manipulate, the rack cylinder does not move or moves very little. At this time, check whether the piston and piston rod seal is too tight, whether it enters the dirt and gum deposits: whether the shaft line of the piston rod and the rack cylinder is in the center, whether the wearing parts and seals are invalid, and whether the load is too large.

The coordination of the sliding parts of the rack cylinder itself should not be too tight, the sealing friction force should not be too large, and H8 / f8 coordination should be selected between the piston rod and the guide sleeve; Check whether the size of the sealing ring is processed strictly according to the standard; If the V-shaped sealing ring is used, the sealing friction should be adjusted to a moderate degree.

How long can a hydraulic cylinder work continuously?

If the maintenance is good, the service life can be extended a lot. The life of the cylinder is related to the structure of the cylinder, working pressure, stress state, hydraulic oil cleanliness, oil temperature control, maintenance and preventive measures. For example, the cylinder structure, the inner wall of the cylinder has quilting, rolling, chrome plating and other methods, the sealing parts have polyurethane rings, glay rings, metal sealing rings, etc., different combinations, the life difference is dozens of times. Metallurgical system is a typical cylinder application, in 24 hours of work, a year or more can not be shut down, in the middle of continuous work.

What is the difference between hydraulic piston cylinder and plunger cylinder?

The force surface of the piston cylinder is a rod cavity and a rodless cavity, and the force surface of the plunger cylinder is the plunger, the spring return single-acting piston cylinder can also rely on the external force of the spring to achieve return, the double-acting piston cylinder can produce tension, and the plunger cylinder only produces thrust without tension.