Release time:2023-11-14 08:41:53 Hits: Current position: Home > News

This article mainly introduces:

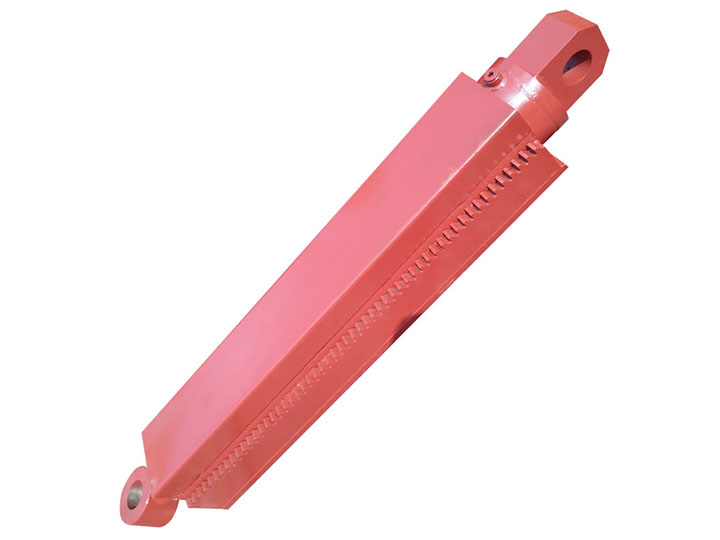

Egypt hydraulic cylinder,single rack cylinder manufacturer,single rack cylinder

(Egypt single rack cylinder,produced by Hengyu Hydraulic Co., Ltd)

single rack cylinder are widely used in Egypt,because of excellent fatigue and impact resistance,no need for deceleration device,long service life.So our company has designed single rack cylinder for customers from Egypt.

What kind of process is used in the single rack cylinder to make high-quality single rack cylinder products: the body is the main component of the single rack cylinder, mining single pillar, hydraulic support, gun tube and other products, and its processing quality directly affects the life and reliability of the entire product. Body processing requirements are high, the internal surface roughness requirements are Ra0.4 ~ 0.8&um, the coaxiality, wear resistance requirements are strict. The basic feature of body is deep hole processing, which has always troubled the processing personnel. The single rack cylinder products of our company mainly use rolling processing, because the surface layer has surface residual compressive stress, which helps to close the surface micro-cracks and hinder the expansion of erosion. Thus, the corrosion resistance of the surface can be improved, and the fatigue crack can be delayed or expanded, and the fatigue strength of the body can be improved. The correct rolling process of the single rack cylinder block: broaching block - fine boring block - grinding block. The rolling method is: broaching block - fine boring block - rolling block, the process is 3 parts, but the time is compared: grinding 1 meter of the block is about 1-2 days, rolling 1 meter of the block is about 10-30 minutes. Input comparison: grinding machine or quilting machine (tens of thousands - millions), rolling knife (ten thousand - tens of thousands). After rolling, the surface roughness of the hole decreases from RA3.2-6.3um before rolling to RA0.4-0.8&um, the surface hardness of the hole increases by about 30%, and the fatigue strength of the inner surface of the single rack cylinder increases by 25%. If the service life of the single rack cylinder is only considered, it is increased by 2 to 3 times, and the efficiency of the boring and rolling process is about 3 times higher than that of the grinding process. single rack cylinder misoperation or operation failure may be caused by the following reasons, you can start from these aspects of the investigation: (1) spool stuck or valve hole blocked. When the spool of the flow valve or direction valve is stuck or the valve hole is blocked, the single rack cylinder is prone to misoperation or operation failure. At this time, the contamination of the oil should be checked; Check whether dirt or colloidal deposits are stuck in the spool or blocking the valve hole; Check the wear of the valve body, clean and replace the system filter, clean the fuel tank, and replace the hydraulic medium. (2) The piston rod and single rack cylinder are stuck or the single rack cylinder is blocked. At this time, no matter how to manipulate, the single rack cylinder does not move or moves very little. At this time, check whether the piston and piston rod seal is too tight, whether it enters the dirt and gum deposits: whether the shaft line of the piston rod and the single rack cylinder is in the center, whether the wearing parts and seals are invalid, and whether the load is too large.

When installing the single rack cylinder pipe, the pipe should be cleaned after installation, and should not pass through the single rack cylinder block, and the by-pass pipe must be installed in front of the oil port of the single rack cylinder block. This is important. Otherwise, the foreign body in the pipeline will enter the single rack cylinder, and once it enters, it is difficult to exclude it, but it becomes a foreign body transported to the single rack cylinder. Moreover, when cleaning, the removal method of foreign bodies entered in the installation pipeline operation should be considered. In addition, the corrosion in the pipe should be pickling and other procedures before the pipe installation, and the rust must be completely removed.

single rack cylinder head explanation: low pressure castings, medium and low pressure with HT300 gray iron, medium and high pressure with 35, 45 steel. When the single rack cylinder head itself is the guide sleeve of the piston rod, the single rack cylinder head is best cast iron. At the same time, brass, bronze or other wear-resistant materials should be fused on the guide surface. If the guide sleeve is pressed into the single rack cylinder head, the guide sleeve shall be wear-resistant cast iron, bronze or brass.

Protection of the single rack cylinder surface: During the dismantling process, safety protection should be carried out on the single rack cylinder to prevent objects from falling and welding slag from falling to the surface, causing damage to the single rack cylinder surface. In the process of propulsion, the damaged pipe segments should be prevented from falling and smashing, and the slurry remaining on the surface of the single rack cylinder should be cleaned up in time.

What is the meaning of dead volume in hydraulic cylinder?

Closed volume, also known as dead zone volume Positive displacement pump is dependent on the change of sealing working volume to achieve suction and pressure oil, in order not to make the suction and pressure oil cavity interworking, there is an oil sealing area between the suction and pressure oil cavity, when the sealing working volume passes through the oil sealing area, neither pressure oil cavity nor oil suction cavity communication, forming a closed sealing volume. The unloading groove is opened, and the grooving principle is that the sealing volume decreases and the oil pressure chamber is communicated, and the sealing volume increases and the oil suction chamber is communicated.

Structural characteristics of the plunger cylinder? (1) The plunger hydraulic cylinder is a single-acting hydraulic cylinder, which can only move in one direction by hydraulic pressure, and the return trip of the plunger depends on other external forces or the weight of the plunger; (2) The plunger is only supported by the cylinder liner and is not in contact with the cylinder liner, so the cylinder liner is easy to process, so it is suitable for long stroke hydraulic cylinder; (3) the total pressure of the plunger during work, so it must have sufficient stiffness; (4) The weight of the plunger is often large, and it is easy to sag due to its own weight when placed horizontally, resulting in wear of the seals and guide side, so its vertical use is more favorable.