Release time:2023-11-08 08:11:37 Hits: Current position: Home > News

This article mainly introduces:

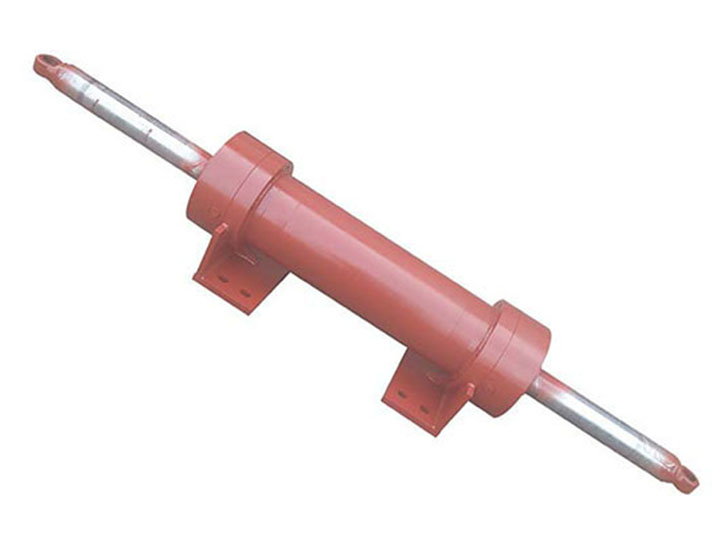

Germany hydraulic cylinder,track steering cylinder manufacturer,track steering cylinder

(Germany track steering cylinder,produced by Hengyu Hydraulic Cylinder Factory)

track steering cylinder are widely used in Germany,because of smooth movement,high work efficiency,excellent fatigue and impact resistance.So our company has designed track steering cylinder for customers from Germany.

When the hydraulic oil is not pumped into the track steering cylinder, it is necessary to check whether the tubing, oil circuit, especially the hose joint has been blocked, and the relevant oil circuit from the track steering cylinder to the pump should be checked in turn and blocked; Check whether the seal between the taper valve and the seat of the relief valve is good; Check whether the solenoid valve spring is damaged or whether the solenoid coil is burned out; Whether the oil circuit is switched is insensitive.

The repair method of track steering cylinder wear: 1. Metal repair material is applied to the scratched surface; The first layer should be thin, uniform and fully covered with the scratched surface to ensure the best adhesion between the material and the metal surface, and then apply the material to the entire repair site and press repeatedly to ensure that the material is filled and reaches the required thickness, so that it is slightly higher than the surface of the guide rail; 2, the material at 24℃ to fully achieve the performance of 24 hours, in order to save time, can be through the tungsten halogen lamp to increase the temperature, the temperature rises 11℃, the curing time will be reduced by half, the best curing temperature 70℃; 3. After the material is cured, use a fine grinding stone or a scraper to repair and smooth the material higher than the surface of the guide rail, and the construction is completed.

When producing oil track steering cylinders, there are two processing processes, grinding and rolling, the latter is better than the former. Rolling machining is a kind of non-cutting machining, using the plastic deformation of the metal at room temperature, so that the micro roughness of the workpiece surface is flattened to achieve the purpose of changing the surface structure, mechanical characteristics, shape and size. Therefore, this method can achieve the two purposes of finishing and strengthening at the same time, which can not be done by grinding.

When the track steering cylinder needs to be disassembled for maintenance due to leakage and other faults, the piston should be moved to the bottom position of the track steering cylinder, and hard beating and sudden drop are strictly prohibited during disassembly.

What is the meaning of dead volume in hydraulic cylinder?

Closed volume, also known as dead zone volume Positive displacement pump is dependent on the change of sealing working volume to achieve suction and pressure oil, in order not to make the suction and pressure oil cavity interworking, there is an oil sealing area between the suction and pressure oil cavity, when the sealing working volume passes through the oil sealing area, neither pressure oil cavity nor oil suction cavity communication, forming a closed sealing volume. The unloading groove is opened, and the grooving principle is that the sealing volume decreases and the oil pressure chamber is communicated, and the sealing volume increases and the oil suction chamber is communicated.

How to calculate hydraulic cylinder thrust?

Cylinder diameter = piston diameter =200MM Piston area =π (200/2) square =3140 square mm =31.4 square cm 25MPA=250KG/ square cm Maximum thrust = pressure * Piston area =250 *31.4 =7850KG=78500 Newtons This is the maximum thrust. The formula can be derived from the calculation formula.