Release time:2023-11-12 15:32:55 Hits: Current position: Home > News

This article mainly introduces:

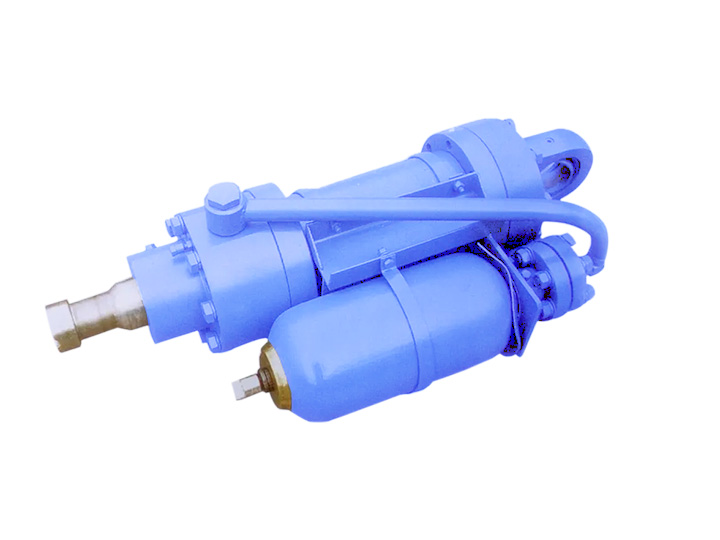

The Philippines hydraulic cylinder,loading cylinder manufacturer,loading cylinder

(The Philippines loading cylinder,produced by Hengyu Group)

loading cylinder are widely used in The Philippines,because of powerful torque,clever hydraulic energy conversion,simple structure and reliable operation.So our company has designed loading cylinder for customers from The Philippines.

The machining accuracy of the loading cylinder depends on the level of equipment, production technology and testing means. loading cylinder processing methods are commonly used in two ways, one is rough boring - fine boring - rolling, generally with 45# seamless steel pipe, this method of processing quality is good, but the cost is high. Another method is to use 20# cold-drawn seamless steel pipe, and then honing, the cost is lower. The piston rod must be adjusted and straightened before processing, and the coating thickness of the piston rod is generally not less than 0.03mm. The piston must be machined in strict accordance with the groove size and tolerance requirements given in the seal manual.

When the loading cylinder is installed on the main engine, the oil port piping part and the guide sleeve should be checked for oil leakage in the running test, and the earring and the middle hinge shaft bearing should be refueled.

The cavitation of the loading cylinder has a great influence, and to avoid it, it is necessary to use the hydraulic oil reasonably and ensure the quality of the hydraulic oil. If the anti-foam property of the oil is poor, it is easy to produce foam, resulting in cavitation. Secondly, the change frequency of oil pressure is too fast and too high, which will also directly cause the formation of bubbles and accelerate the rupture rate of bubbles. The test shows that the speed of cavitation will be accelerated in the part with high frequency of pressure change. For example, at the inlet and outlet of the loading cylinder, due to the relatively high frequency of pressure changes, the degree of cavitation is also relatively higher than that of other parts. In addition, overheating of the oil will also increase the probability of cavitation.

Factors that should be considered when selecting the oil seal in the loading cylinder: some specific factors should be taken into account when selecting the oil seal in the loading cylinder, so as to have correct consideration and get accurate results, and then avoid wrong selection. The factors and aspects that should be taken into account are eight: loading cylinder diameter, piston rod diameter, piston rod and piston groove size, loading cylinder working pressure, loading cylinder movement speed, hydraulic system oil temperature and loading cylinder working environment.

Why does the tipping bucket cylinder have a cylinder withdrawal problem?

This problem may have a certain relationship with the operation of the driver, the main reasons are the following two situation analysis: 1, the current domestic loader working device is mostly a six-link mechanism, the six-link mechanism in the bucket to the limit position, lift the boom, the rotating bucket cylinder will appear "cylinder pulling" phenomenon, that is, the piston rod of the rotating bucket cylinder will be pulled out. In this case, in order to protect the cylinder, a pressure overload protection valve with large and small cavities is provided on the multi-way valve rotating bucket link (large chamber 18MPa, small chamber 12MPa). 2, before the cylinder is assembled to the whole machine, the cylinder is not limited, the piston rod of the cylinder can be pulled in place before and after, but when it is installed on the whole machine, in order to avoid the cylinder pulling out, the limit switch is installed according to the regulations.

CNC lathe rotary cylinder oil leakage and treatment methods

Oil leakage often occurs when the cylinder (especially the hollow cylinder) of the CNC lathe is installed. First check the cylinder yaw, be sure to reach or close to the required value, generally the cylinder requires the outer beat within 1 wire. Otherwise, too much beating is sure to leak oil. Then check whether the tubing is smoothly downward at a certain Angle, and can not bend. Look at the pipe outlet can not go into the oil level, to a little higher. Otherwise, there's back pressure and it's gonna leak.