Release time:2023-11-12 15:32:10 Hits: Current position: Home > News

This article mainly introduces:

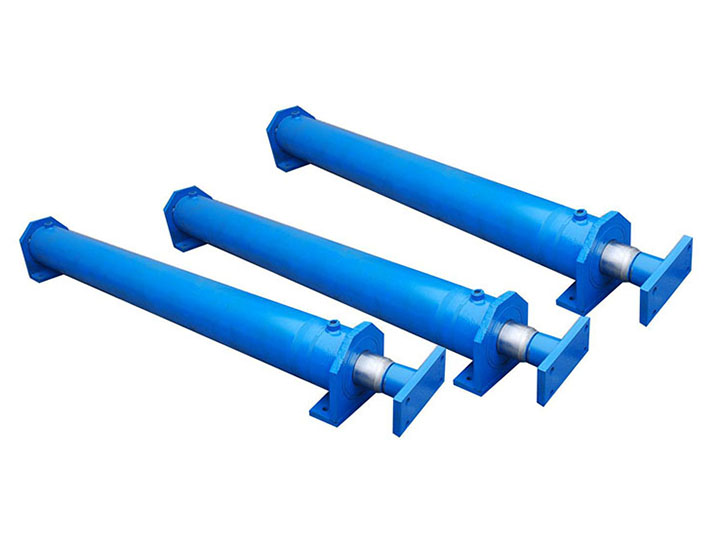

Tunisia hydraulic cylinder,push and pull the cylinder manufacturer,push and pull the cylinder

(Tunisia push and pull the cylinder,produced by Hebei Hengyu company)

push and pull the cylinder are widely used in Tunisia,because of clever hydraulic energy conversion,clever hydraulic energy conversion,high work efficiency.So our company has designed push and pull the cylinder for customers from Tunisia.

When the push and pull the cylinder is installed, the piston and the push and pull the cylinder head and other parts have large mass, large size and large inertia, even if there is a lifting equipment auxiliary installation, because the specified clearance is small, no matter how hard it will be put into, therefore, the end of the piston or the push and pull the cylinder head boss is easy to cause scars when it hits the inner surface of the push and pull the cylinder wall. The solution to this problem: for a large number of small products, the use of autocratic assembly oriented tools during installation; For heavy, thick and large large and medium-sized push and pull the cylinders, only careful and careful operation can be avoided.

If the push and pull the cylinder slips or crawls, please check whether there is astringency inside the push and pull the cylinder, because the internal parts of the push and pull the cylinder are improperly assembled, the parts are deformed, worn or the shape and position tolerance is excessive, the action resistance is too large, so that the piston speed of the push and pull the cylinder changes with the different stroke position, and the slip or crawl occurs. Most of the reasons are due to poor assembly quality of parts, surface scars or sintered iron filings, so that the resistance increases, the speed decreases. For example, the piston is different from the piston rod or the piston rod is bent, the push and pull the cylinder or the piston rod is offset from the mounting position of the guide rail, and the sealing ring is too tight or too loose. The solution is to repair or adjust, replace damaged parts and remove iron filings.

When the push and pull the cylinder is installed on the main engine, the oil port piping part and the guide sleeve should be checked for oil leakage in the running test, and the earring and the middle hinge shaft bearing should be refueled.

The viscosity of the working oil used in the push and pull the cylinder is 29~74mm2/S, and ISO VG46 anti-wear hydraulic oil is recommended. Working oil temperature within the range of -20~80. C. When the ambient temperature and service temperature are low, the oil with lower viscosity can be selected.

How to produce good quality hydraulic cylinder?

According to the principle of quality control, it is considered from five aspects: people, machine, material, method and environment. 1, People, refers to the processing and assembly operators. Their skills, professional qualifications, literacy should meet the requirements of production. For example, do your machining workers have the required grade certificate? Do your welders have welding certificate? 2, Machine, refers to your production equipment. Production cylinders have requirements for processing equipment. For example, the piston rod requires chrome grinding. Can your equipment meet the need? 3, Material. The material you use should meet the quality requirements. For example, the sealing ring of PARK and domestic goods is different. Material is also very important. 4. Method refers to the process method. Do your processing and assembly processes meet the requirements? 5, Environment. The environment shall be neat and orderly, clean and hygienic. It is especially important for the hydraulic cylinder production enterprise environment. Can your assembly shop site be clean and dust-free? Quality inspection is also a focus of control. Products should do pressure test, leakage test. The test pressure should reach 1.25 times the design pressure. If you can't maintain pressure, what about quality? You may not be able to do the whole process of cylinder production, you can take the method of OEM. Taking advantage of the strengths of specialized manufacturers, you contract out what you need and then assemble it yourself. But the principle of quality control is the same.

How to refuel pneumatic riveting cylinder?

First put the gun flat, that is, horizontally, while pushing the stroke positioning pin and loosen the back cover, rotate to the left for a maximum of five turns, and then use a wrench to loosen the oil sealing screw, slowly add the hydraulic oil and let the air out, fill up to tighten the oil sealing screw. This process of adding hydraulic oil is over.